- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: China

- Brand Name: Zhuchengdongshang

- Model Number: Processing customization

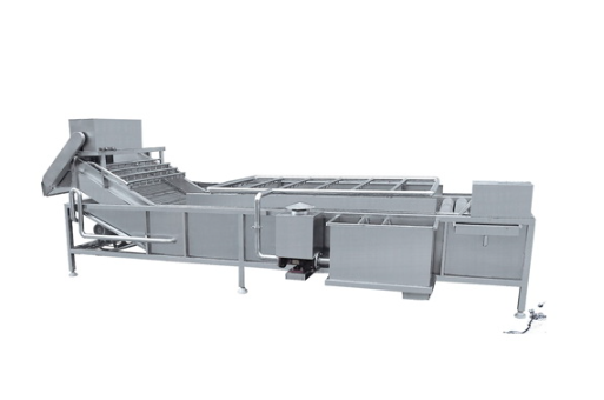

Bubble cleaning machine specification, Equipment Overview: the equipment in the bubble, surfing, lifting, spraying and other joint work, with a clean high, energy saving, equipment, stable and reliable characteristics. The utility model is suitable for cleaning of raw fruits and vegetables; washing water after filtration cycle; with lifting, convenient connection; according to the characteristics of fruits and vegetables and process requirements of design; equipment made of stainless steel with QS and GMP requirements; electronic control cabinets make the operation more convenient, fast and effective length of human nature; effective width type production capacity of T/H power KW CXJ - 2020 - 405.61200400 - 1010 - 154.058003000 according to the requirement of CXJ according to the requirements of CXJ - 54 - 82.86002600 - 21 - 31.474002300 according to the requirements of CXJ, according to the requirements of two steps: 1, check whether the various components of the equipment in good condition, after the inspection, when the water inlet valve open up return level, off a small valve, open the blast circulating water pump , conveyor belt, the material into the sieve plate, regulate the circulating water pump pressure to ensure material in water residence time in order to ensure more thorough cleaning of materials according to the difference of the material. Adjust the speed of the conveyor belt to the material once again spray cleaning in the process of filtering out of water; the material by the conveyor belt flow into the box back. 2, the use of the process should be based on the different materials to clean up the filter regularly, regular cleaning, sewage; appropriate adjustment of water and spray water to make cleaning more water-saving. 3, conveyor belt drive reducer with adjustable structure, the user can adjust the transmission speed according to different materials to make the material two times spray cleaning, filter water more thoroughly in order to improve the utilization rate of equipment.

- Place of Origin: China

- Brand Name: Zhuchengdongshang

- Model Number: Processing customization

Bubble cleaning machine specification, Equipment Overview: the equipment in the bubble, surfing, lifting, spraying and other joint work, with a clean high, energy saving, equipment, stable and reliable characteristics. The utility model is suitable for cleaning of raw fruits and vegetables; washing water after filtration cycle; with lifting, convenient connection; according to the characteristics of fruits and vegetables and process requirements of design; equipment made of stainless steel with QS and GMP requirements; electronic control cabinets make the operation more convenient, fast and effective length of human nature; effective width type production capacity of T/H power KW CXJ - 2020 - 405.61200400 - 1010 - 154.058003000 according to the requirement of CXJ according to the requirements of CXJ - 54 - 82.86002600 - 21 - 31.474002300 according to the requirements of CXJ, according to the requirements of two steps: 1, check whether the various components of the equipment in good condition, after the inspection, when the water inlet valve open up return level, off a small valve, open the blast circulating water pump , conveyor belt, the material into the sieve plate, regulate the circulating water pump pressure to ensure material in water residence time in order to ensure more thorough cleaning of materials according to the difference of the material. Adjust the speed of the conveyor belt to the material once again spray cleaning in the process of filtering out of water; the material by the conveyor belt flow into the box back. 2, the use of the process should be based on the different materials to clean up the filter regularly, regular cleaning, sewage; appropriate adjustment of water and spray water to make cleaning more water-saving. 3, conveyor belt drive reducer with adjustable structure, the user can adjust the transmission speed according to different materials to make the material two times spray cleaning, filter water more thoroughly in order to improve the utilization rate of equipment.